A. HATZOPOULOS S.A. and ROVEMA present a high-performance monomaterial solution for coffee packaging at Warsaw Pack, Poland.

A. HATZOPOULOS S.A. and leading machine manufacturer ROVEMA join forces to present live at the upcoming Warsaw Pack trade fair in Poland a fully-recyclable solution for coffee packaging, running at full speed at the ROVEMA’s BVC 260 packaging machine live on display at the show. Ensuring high-barrier properties for the protection of the coffee’s aroma and flavors, the monomaterial film which we designed based on the X-CYCLE™ packaging technology delivers packaging sustainability, efficiency and full performance.

Mono-material, all-PP Recyclable solution based on X-CYCLE™

The high-end X-CYCLE™ materials we developed specifically for the coffee market are in line with the industry guidelines for flexible packaging design for recycling, strongly suggesting the replacement of conventional flexible packaging with mono-material alternatives, in order to facilitate recycling. The specific target for the development of this film was to convert conventional structures, which are used for coffee packaging, into their recyclable equivalents, whilst simultaneously preserving the high protective and functional properties of the original films. This particular solution we designed replaces the traditional multi-material coffee triplex laminates with a mono-material, 89my formulation constructed exclusively from polypropylene films and thus it can be easily recycled through the PP recycling streams already existing in several European countries.

High Protection

The monomaterial packaging film to be presented live at the event incorporates high-barrier properties against oxygen, aroma and water vapor. This way it is able to provide total safety and guarantee high protection of the coffee quality, maintaining the aromas and the various coffee flavors rich and vibrant for a long shelf-life.

Full Performance

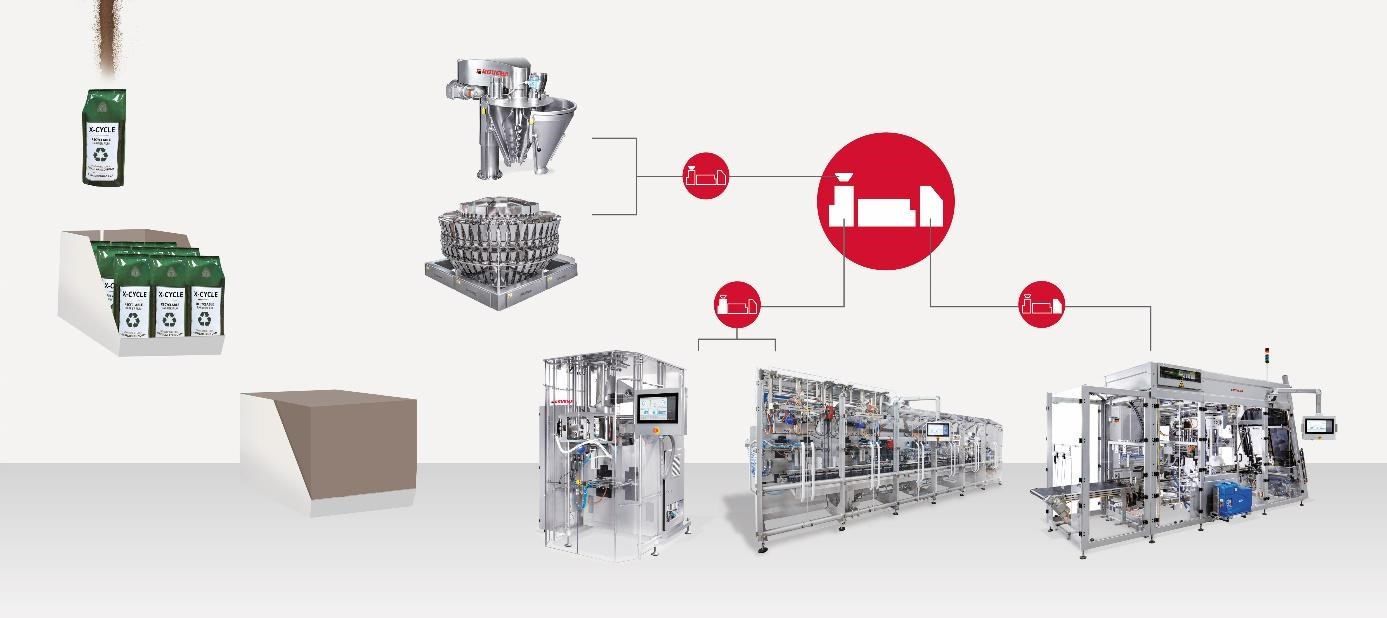

The switch to the suggested X-CYCLE™ film is easy and efficient, as it achieves optimal performance during the packing process. First approved at ROVEMA’s test center in Germany and now presented live at Warsaw Pack in Poland, this fully-recyclable packaging system we have designed reaches an output rate of up to 70 stable, side-gusseted coffee packs per minute, with the WICOVALVE® W109PP button valve applied ultrasonically to our X-CYCLE™ PP film at ROVEMA’s BVC 260 line on display at the show.

Many coffee brands now decide to follow a holistic approach to Sustainability in their supply chain, going beyond their coffee sourcing and looking to switch also their packaging into more sustainable alternatives. At A. HATZOPOULOS S.A. we are committed to help our partners achieve their current and future sustainability goals. With the vision for a better future planet, we have developed the next generation of flexible packaging solutions for coffee, designed for recycling: X-CYCLE™.

Warsaw Pack 2024 will take place on 23-25 April 2024. The event will bring together leading companies, technical experts and practitioners from the entire Central and Eastern European region and it is expected to attract more than 20.000 visitors. Discover our innovative X-CYCLE™ materials live at the ROVEMA stand: Hall 5, Stand F5.19.

Practical info:

![]()

Venue

Ptak Warsaw Expo Al. Katowicka 62 05-830 Nadarzyn, Poland

Hall 5 | Stand F5.19

![]()

Dates & schedule

Tuesday, April 23: 10:00am-5:00pm

Wednesday, April 24: 10:00am-5:00pm

Thursday, April 25: 10:00am-5:00pm

About ROVEMA:

With passion and the experience of more than 60 years, ROVEMA develops and builds packaging machines and lines that meet the complex demands of the modern circular economy. ROVEMA thinks holistically and considers the environment, the market, the product and the packaging in projects from the very beginning. This enables the development of efficient and sustainable packaging machines with high availability. A sustainable solution that fits the characteristics of the product to be packaged and its requirements for logistics, packaging material, shelf life and energy efficiency is ROVEMA’s top priority. A successful concept – ROVEMA has already delivered more than 30,000 machines and lines worldwide.

At the Warsaw Pack trade show ROVEMA is exhibiting a BVC 260 of continuous operation specifically for packing coffee – ground coffee, coffee beans, agglomerated or freeze-dried coffee can be processed with gentle product handling and accurate weight. For coffee applications requiring a degassing valve, the machine is equipped with the particularly high-performance new ROVEMA valve applicator for button valves. Packing materials from the flat film web are used, and the aroma valve is fitted in the reel carrier of the packaging machine, offering maximum flexibility at this point as well: the process allows an even wider sealing window, which can be adapted to the requirements of the particular packing material and the button valve selected.